The realization of an intractable dream: the engineering genius behind the Bugatti Veyron [Photo Gallery]

A vehicle that could reach 400 km/h in the morning, yet be a picture of elegance driving to the opera in the evening. This was the dream of ingenious engineer and then-Chairman of the Volkswagen Group, Ferdinand Karl Piëch. A visionary who, in 1997, began the journey of conceptualizing the Bugatti Veyron – a new breed of car, a hypercar, that could realize his ambition.

Realizing such capability in a road-going vehicle had not been achieved in the history of the automobile. It was a monumental challenge that demanded a masterstroke of engineering and intelligent design; one that only the finest automotive minds could conquer.

A series of intractable physics problems stood in the way of Piëch, Bugatti’s master engineers, and creating what would become one of the most iconic vehicles of all time. Fundamentally, the marque would need to deliver a car that could withstand the immense forces subjected to it at a third of the speed of sound. That required a wholesale change in vehicle design approach – right down to the tires, none of which in existence could take on the challenge. The tires themselves aptly symbolized the scale of the task at hand – ultimately taking a supplier five years to develop a solution capable of managing the performance of Piëch’s vision.

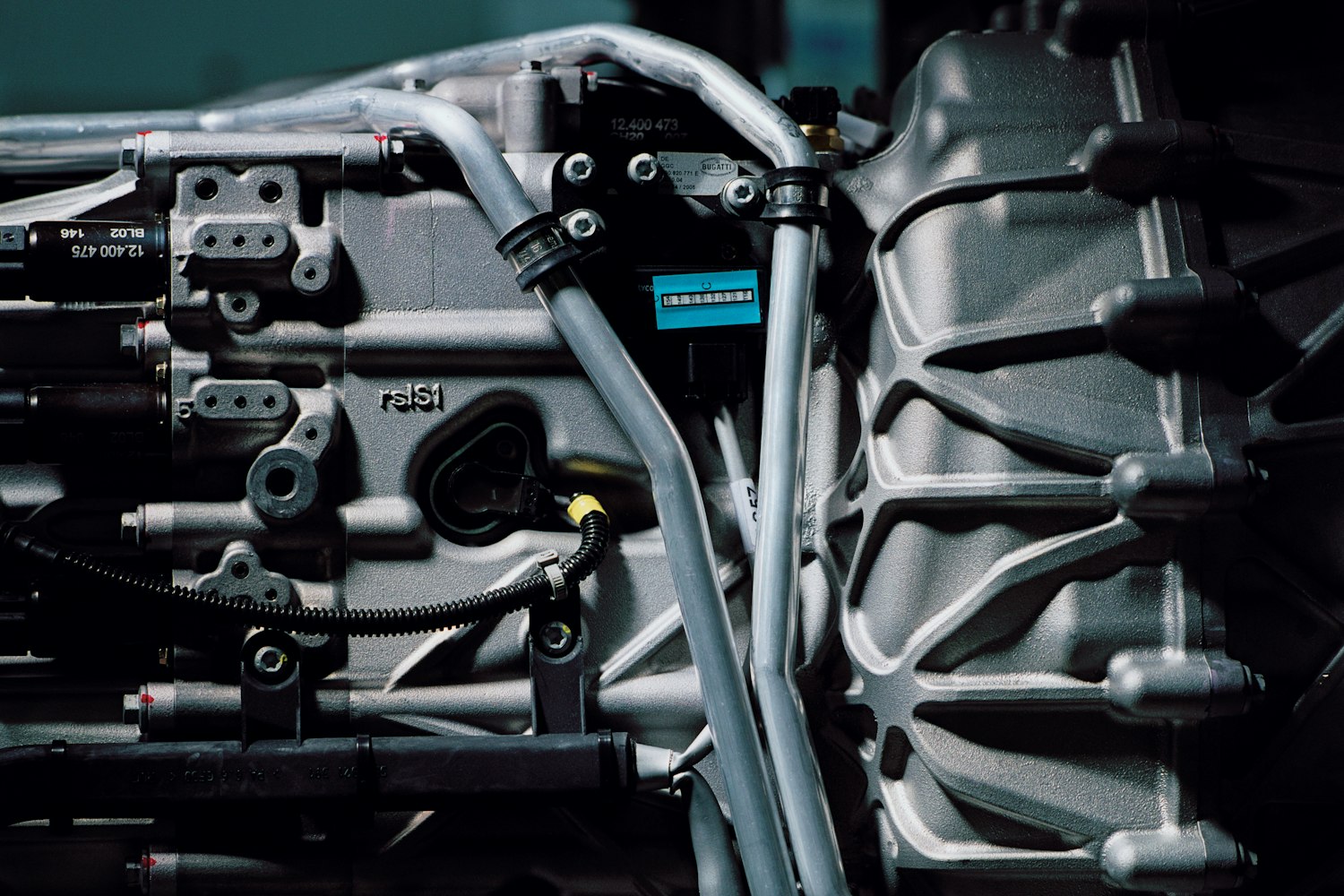

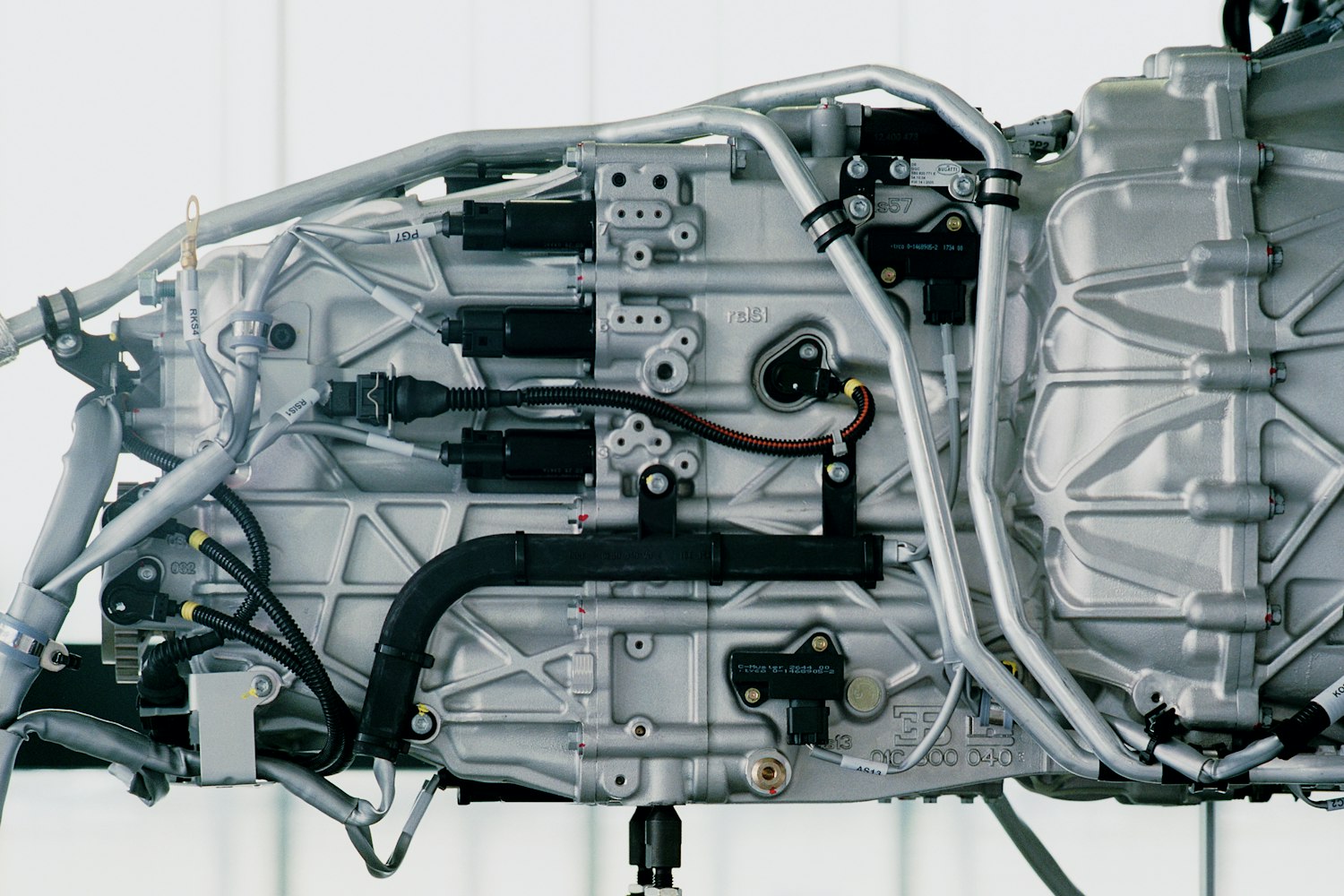

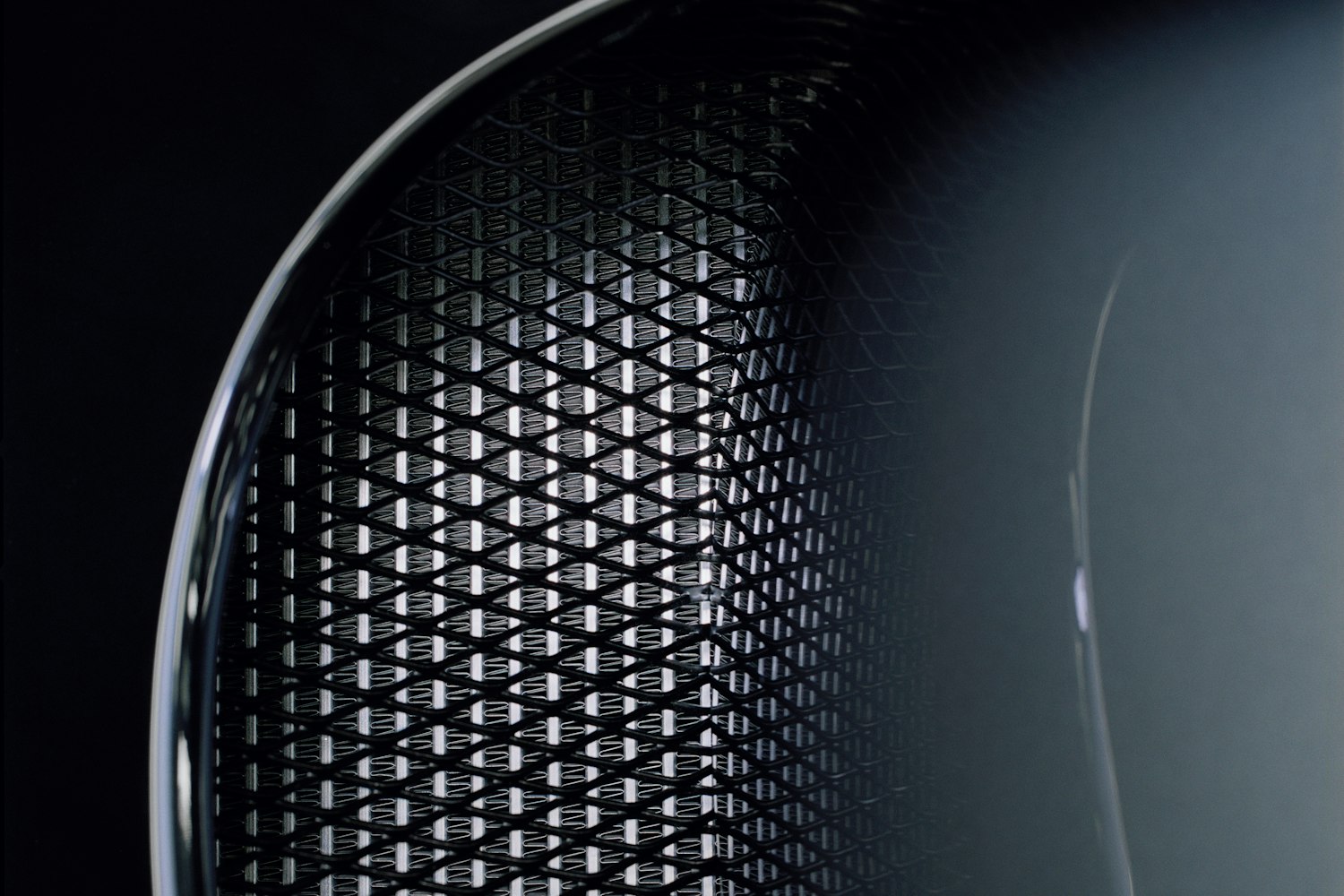

The starting point for the vehicle, however, was the engineering marvel that would come to propel the Veyron at previously unimaginable speed: its W16 engine. Newly developed from scratch, the W16 was designed with an 8.0-liter displacement, reinforced with four turbochargers and ten radiators to provide sufficient cooling. The result was a powerplant that could seamlessly deliver 1,001 PS at 6,000 rpm, and 1,250 NM of torque between 2,200 and 5,000 rpm – unprecedented numbers that needed an equally momentous achievement in powertrain and drivetrain engineering to harness effectively. In turn, another first was required – a seven-speed, double-clutch DSG gearbox with lightning-fast yet smooth gearchanges that was specifically designed for the Veyron, and able to cope with its power and torque output.

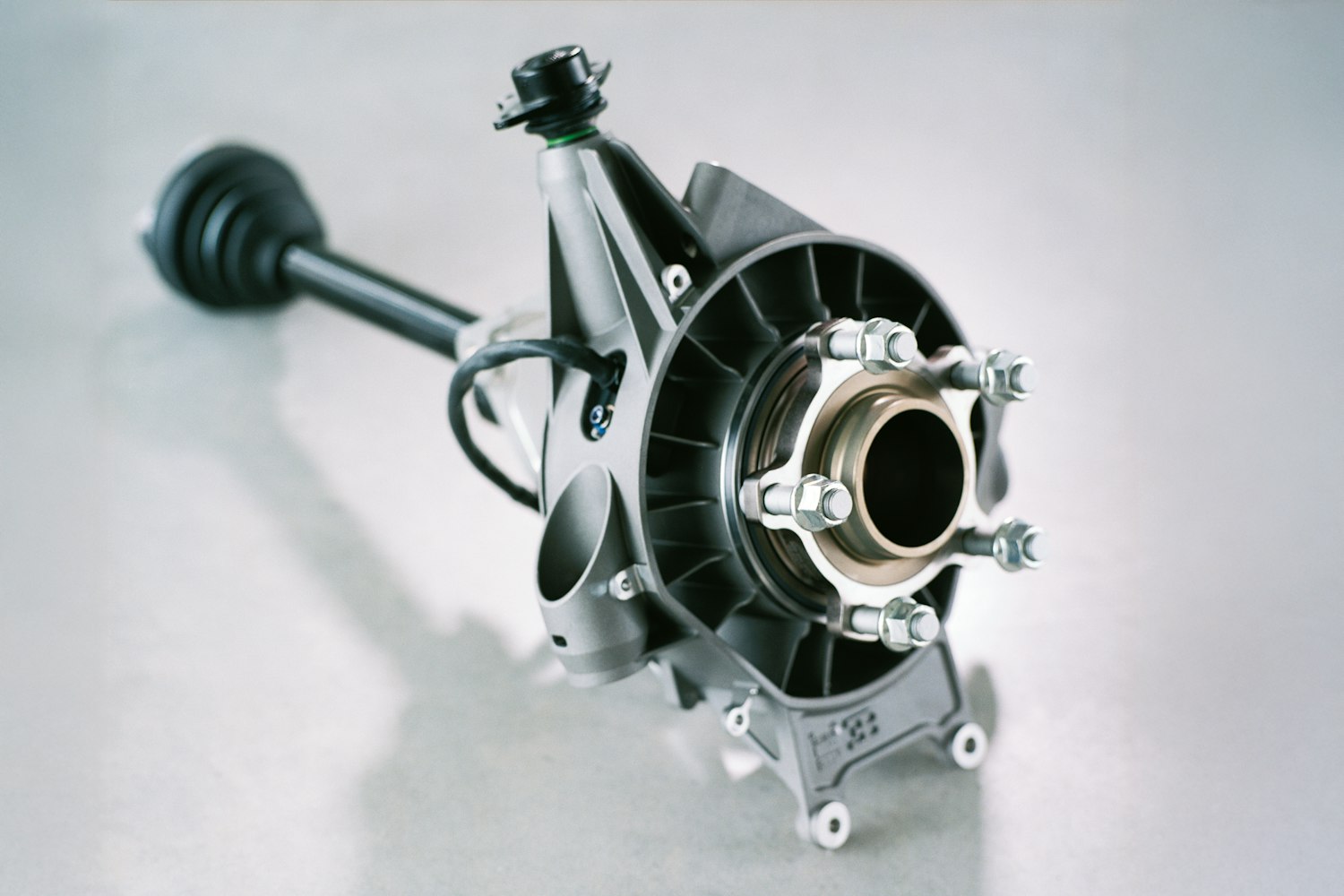

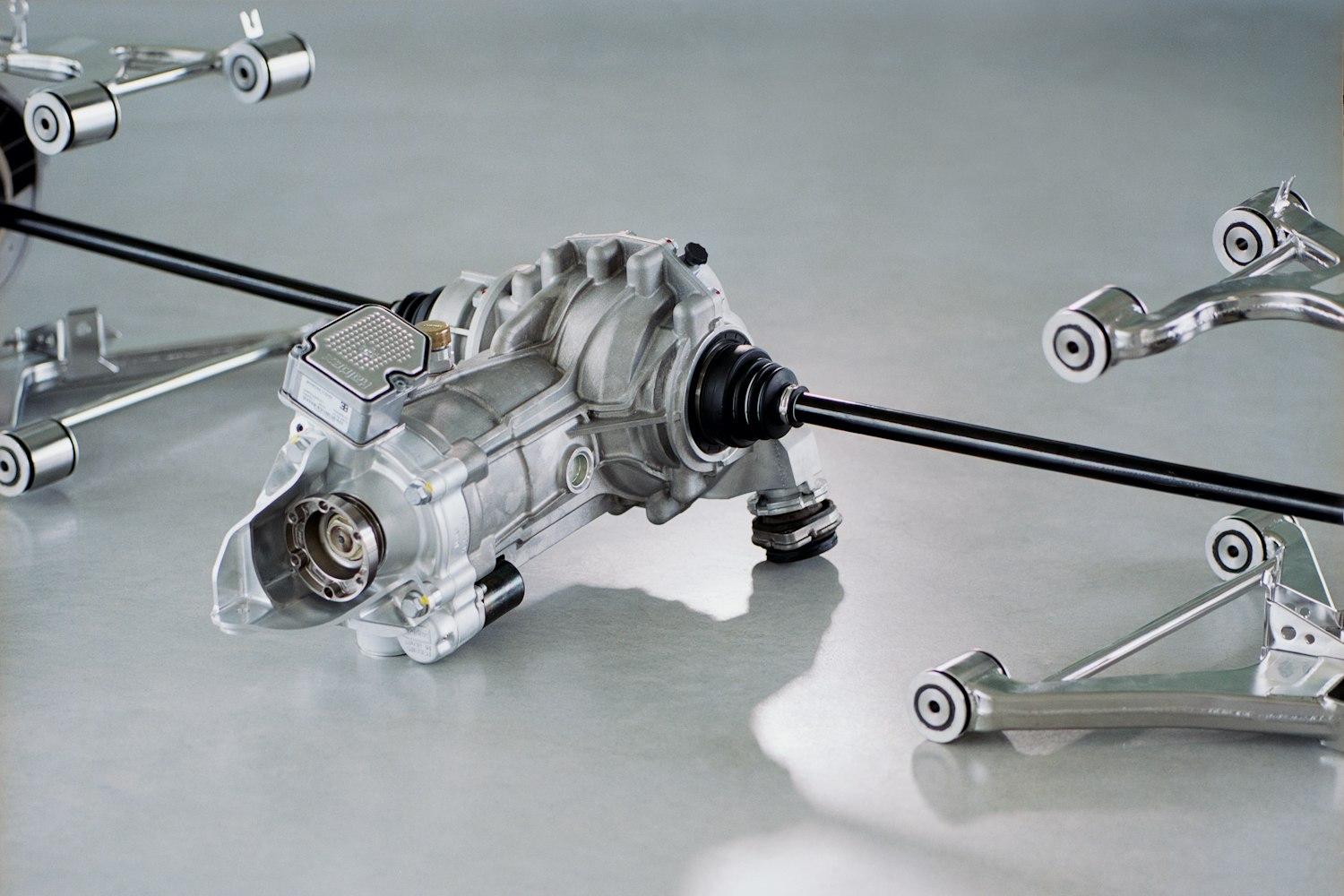

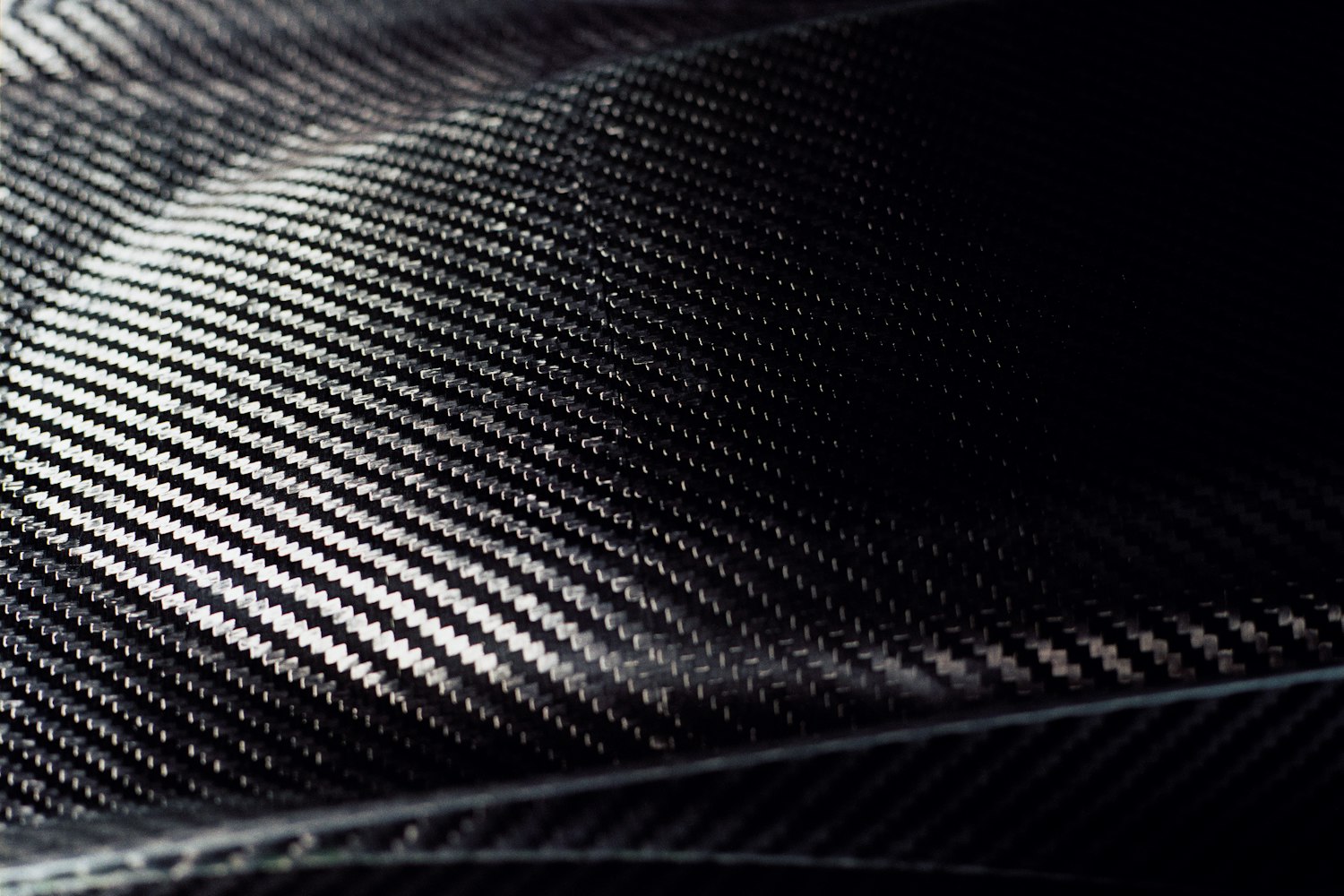

Arranged longitudinally ahead of the W16 engine, the gearbox – just like the powerplant – was designed as a dry sump unit, playing a pivotal role in allowing Bugatti’s engineers to lower the car’s center of gravity. That decision was part of a critical program to set the car up for strong road-holding capability – a characteristic completed by the combination of the immense dynamic tolerances of the fully integrated carbon fiber monocoque, aluminum chassis, and all-wheel drive drivetrain.

Employing a transmission unit integrated behind the front-axle differential, the cutting-edge all-wheel drive system allows perfect distribution of power between the front and rear axles, optimizing balance through challenging twists and turns – while a multi-disc transverse lock on the rear differential ensures peak traction coming out of them.

And yet, Ferdinand Piëch’s vision for the Veyron would be unachievable, without a highly efficient yet beautiful design capable of working in harmony with the forces of air at high speed. At its core, integrated elegantly into the car’s smooth profile, is an adaptive aerodynamics system tested to perfection by then-head of development of Bugatti, Dr. Wolfgang Schreiber. Managed by a variable control system, the adaptive aerodynamics consist of two diffuser flaps ahead of the front wheels, and an integrated wing and spoiler at the rear of the car.

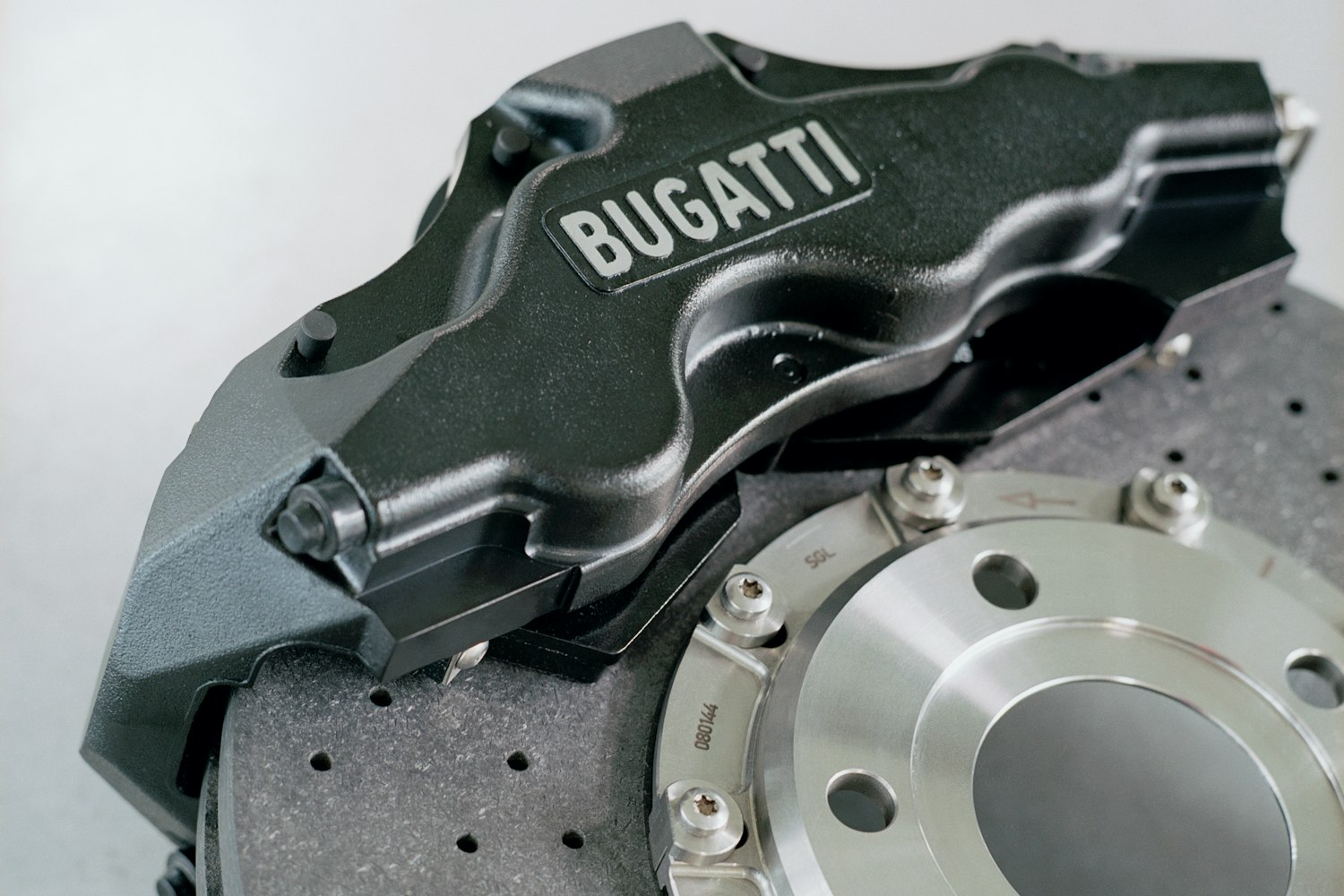

Supporting the Veyron’s unique carbon-ceramic, high-performance braking system, the rear aerofoil also utilizes the high wind resistance experienced at speeds over 200 km/h, becoming a formidable ‘air brake’. In ‘Handling’ configuration, the driver activates the system when a specific level of braking pressure is exceeded between 200 and 375 km/h, with the aerofoil shifting itself to an angle of 113 degrees to the direction of travel in just 0.4 seconds. The ingenious solution not only enhances wind resistance under significant braking, but also generates 300 kilograms of downforce over the rear – reducing the wheel load displacement experienced under rapid deceleration and maintaining the vehicle’s hallmark stability.

Each component of the active aerodynamics set-up thus works together to produce hundreds of kilograms of downforce – but critically, to significantly reduce drag when setting off in the pursuit of the Veyron’s incredible top speed.

In every sense, reaching 400 km/h is a feat unlocked by the hypercar’s intelligent aerodynamics. Achieving this requires a conscious, deliberate decision by the driver and a specific vehicle setup. The Veyron is prepared for this extreme performance through the use of its bespoke ‘Speed Key’ – a secondary key that must be inserted into a cylinder to the left of the driver’s seat before setting off. Turning it, the vehicle hunkers down in a raked stance – its active suspension taking it a mere 65 millimeters above the ground at the front, and 70 millimeters at the back. While simultaneously, the front diffusers remain closed, and the angle of the rear wing arrangement is reduced – all to minimize air resistance.

Together, the concept of the Veyron’s immense power delivery and aerodynamic capability sets the car up for achieving the unthinkable. And precisely because of its unprecedented nature, the journey needed to be defined by a meticulous and extensive program of in-field testing. Eleven dedicated vehicle prototypes took up the mantle, together accumulating hundreds of thousands of kilometers in testing under the toughest conditions conjurable for the vehicle.

While some cars underwent long-distance testing, others were subjected to a series of function tests, simulating the full gamut of driving scenarios to repeatedly test the vehicle’s range of operational systems and features. Even the notorious Green Hell, Germany’s Nürburgring, was called upon to test the Veyron’s mettle – with test vehicles amassing thousands of kilometers at full racing speed around the circuit.

Fittingly, the culmination of the Veyron achievement came in 2005, a matter of months before it entered full-scale production at Bugatti’s spiritual home in Molsheim. With the skilled hands of test driver Uwe Novacki at the wheel of the hypercar, the Veyron became etched into the annals of automotive history – the excellence of its engineering and design coming together to realize the 400 km/h dream, and earning an official top speed of 407 km/h. An accomplishment that saw the Veyron take its place, at that very moment, as the fastest production vehicle in history.