Seamless integration: the packaging strategy behind the Bugatti Tourbillon [Photo Gallery]

Every Bugatti is a carefully balanced composition where design, performance and innovation are meticulously coordinated to create something greater than the sum of its parts. In the Tourbillon¹, this approach is taken further than ever before. Episode 9 of the ‘Bugatti: A New Era’ documentary series, now available on YouTube, explores the hypercar’s packaging.

It is a story not just of engineering, but of thoughtful architecture and aerodynamic intent, where every element plays a role in achieving the Tourbillon’s extraordinary performance.

‘When you develop a car, especially from scratch, you can never look at a single component individually without taking the whole context of the car into account,’ said Mate Rimac, CEO of Bugatti.

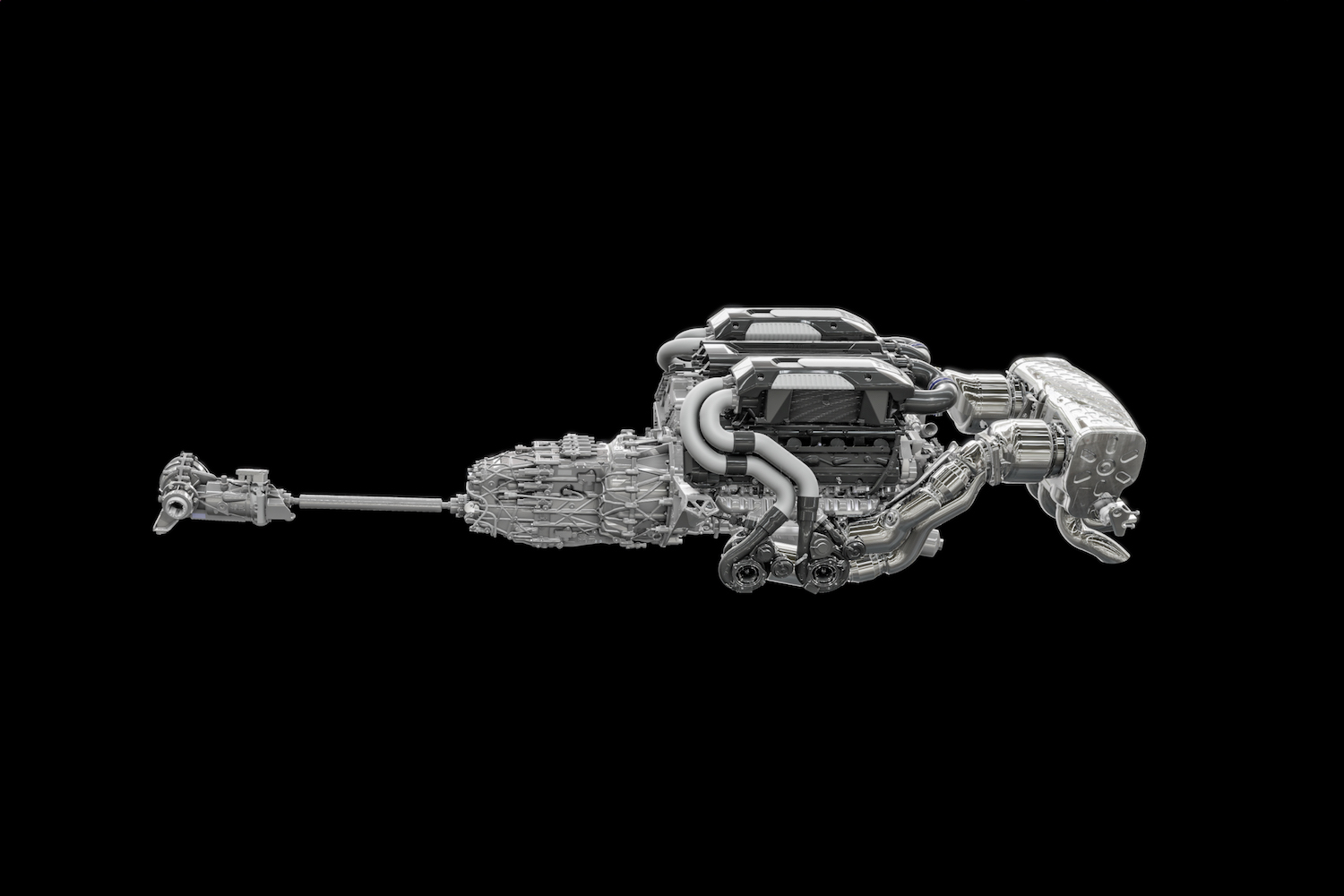

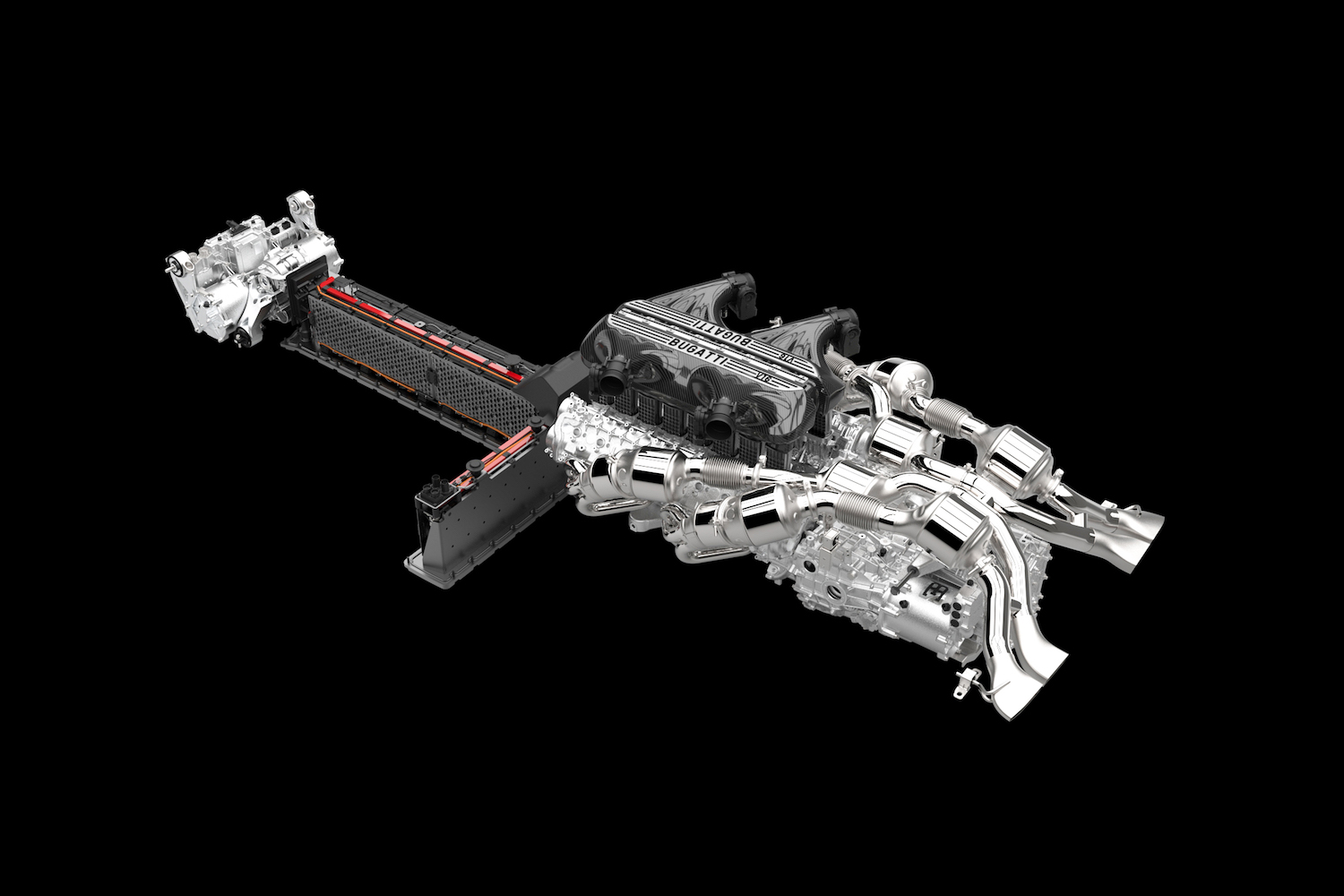

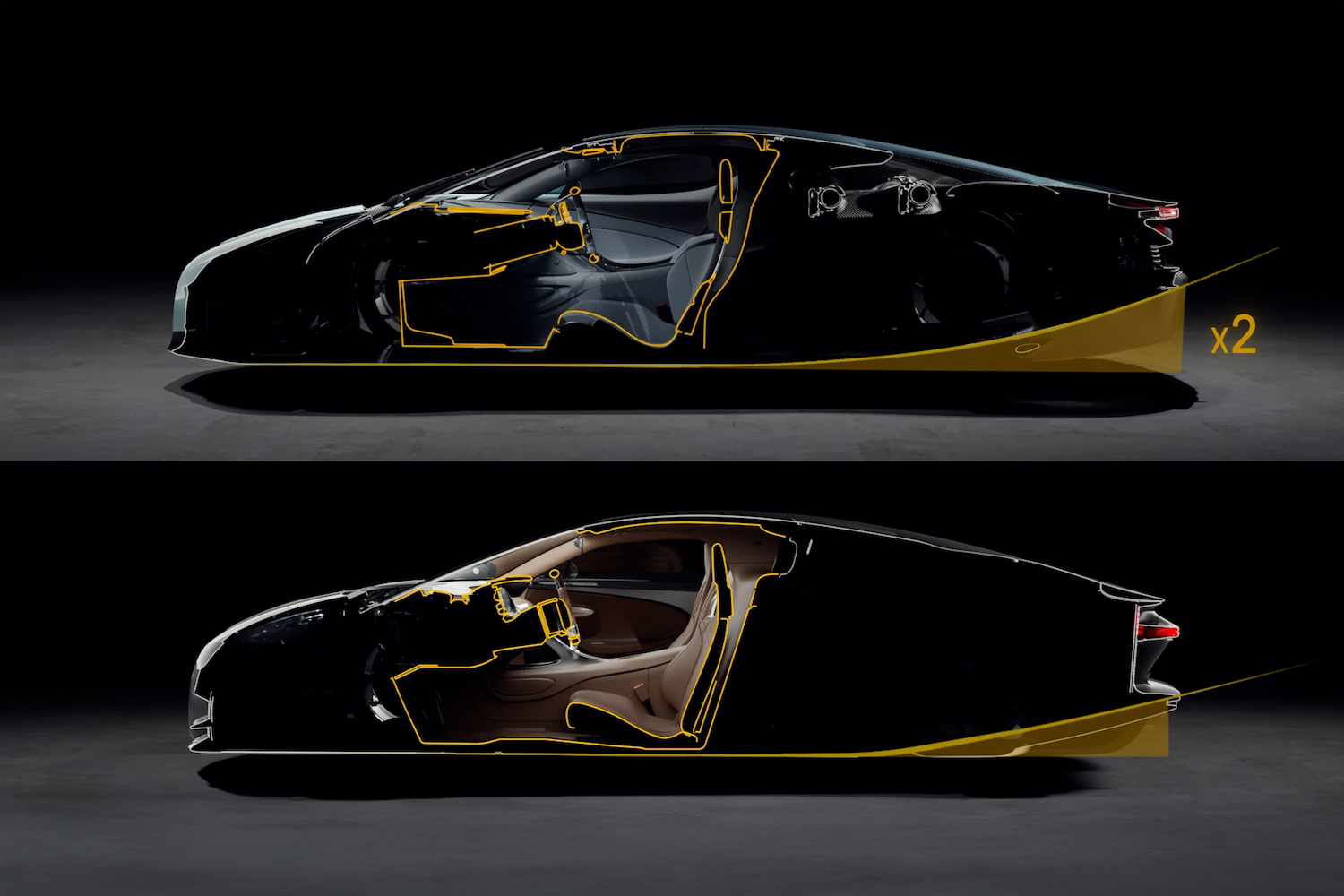

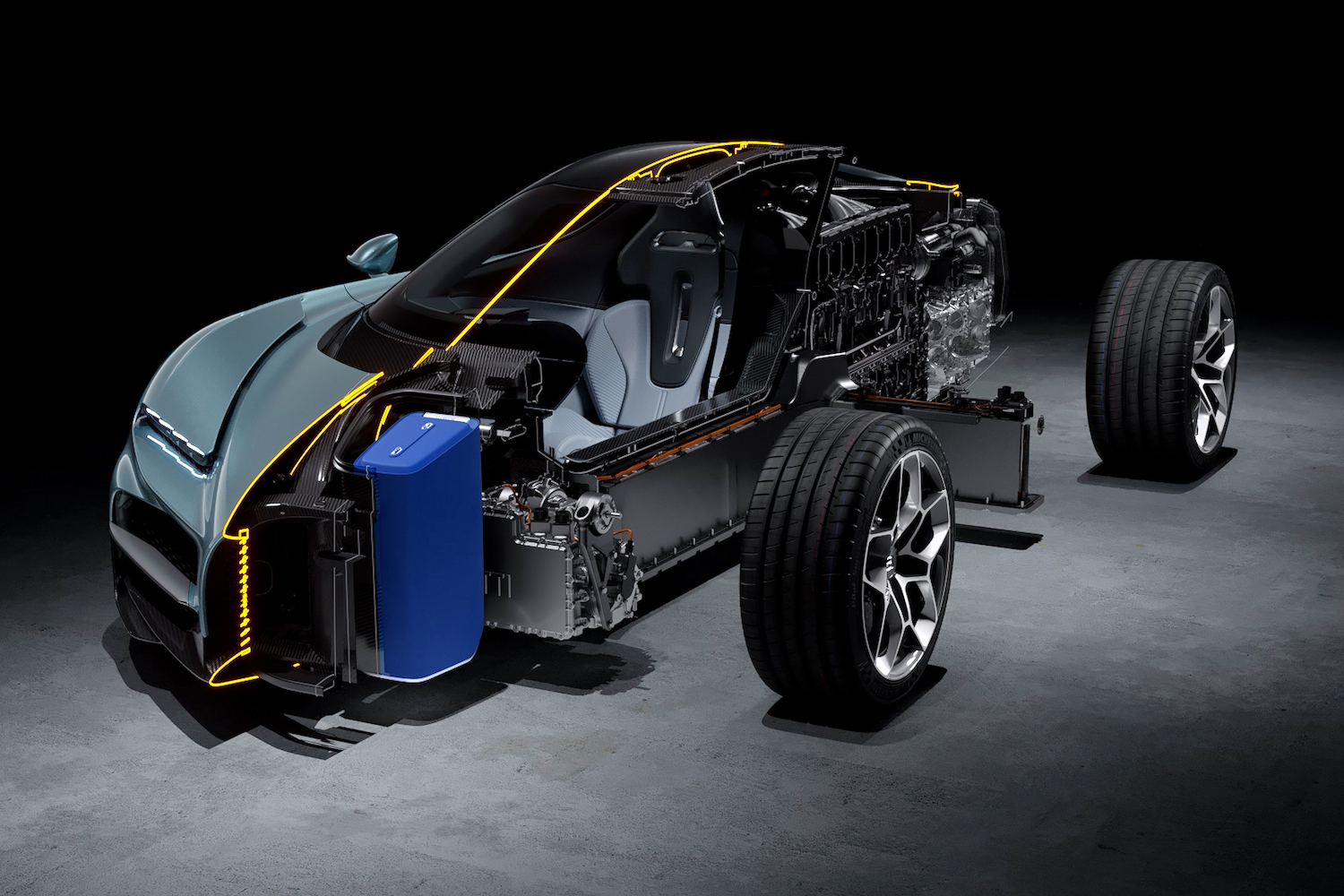

The Tourbillon’s packaging represents a dramatic shift: the new V16 engine, longer and narrower than the outgoing W16, is mounted at an angle. This change, while subtle in appearance, is profound in impact, allowing the engineers to create super-long Venturi tunnels for the diffuser, which starts beneath the cabin and extends nearly halfway down the vehicle’s length.

These tunnels are crucial to the car’s aerodynamic efficiency, as they generate significant downforce from beneath the car rather than relying on wings above. This approach delivers more downforce with less drag, allowing the Tourbillon to reach its maximum speed without deploying the rear wing.

The massive diffuser is only possible thanks to an innovative powertrain layout. The gearbox, traditionally placed in front of the engine, now sits behind it. The front axle is powered independently by dual electric motors, which means there is no physical, mechanical connection between the engine and the front wheels. Between the front and rear motors sits a compact battery, enabling more efficient packaging and optimal weight distribution.

This redesign also allowed for a reduction in frontal area – something that was essential for a hypercar aiming to surpass the Chiron²’s speed benchmarks.

‘People sometimes forget that total dynamic resistance of a car is the drag coefficient times the frontal area. So, it’s really important to reduce the frontal area, especially for a hypercar that goes the speeds that we do,’ added Rimac.

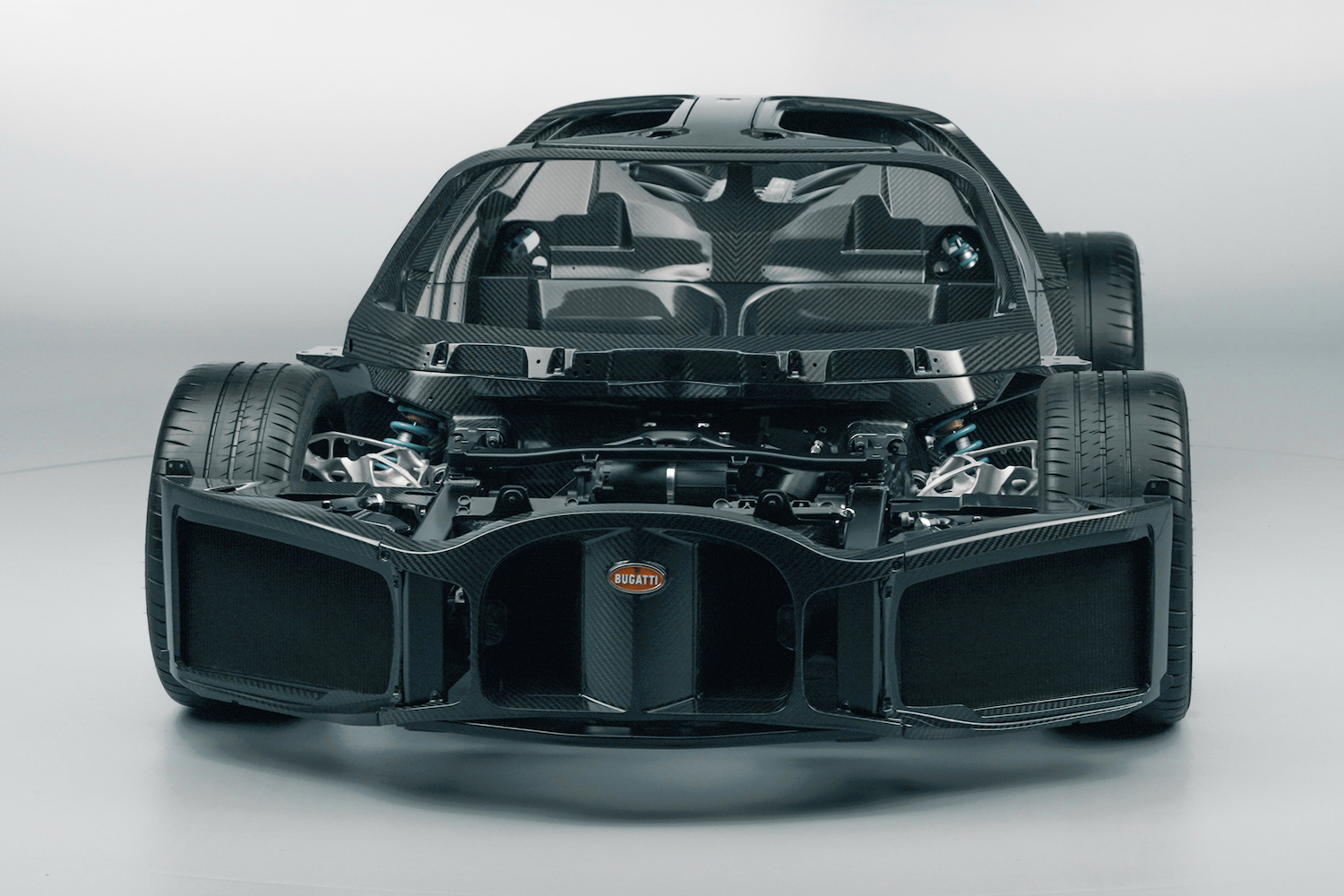

Aerodynamics, thermodynamics and structure converge at the front, where the iconic Bugatti horseshoe is more than just a design motif. It serves as an interface for cooling. Even in its naked form, without bodywork, the Bugatti horseshoe remains. Air flows from the grille, past the luggage compartment, cooling the front electric axle, the battery and the brake system. To the left and right of the grille is the cooling for the combustion engine.

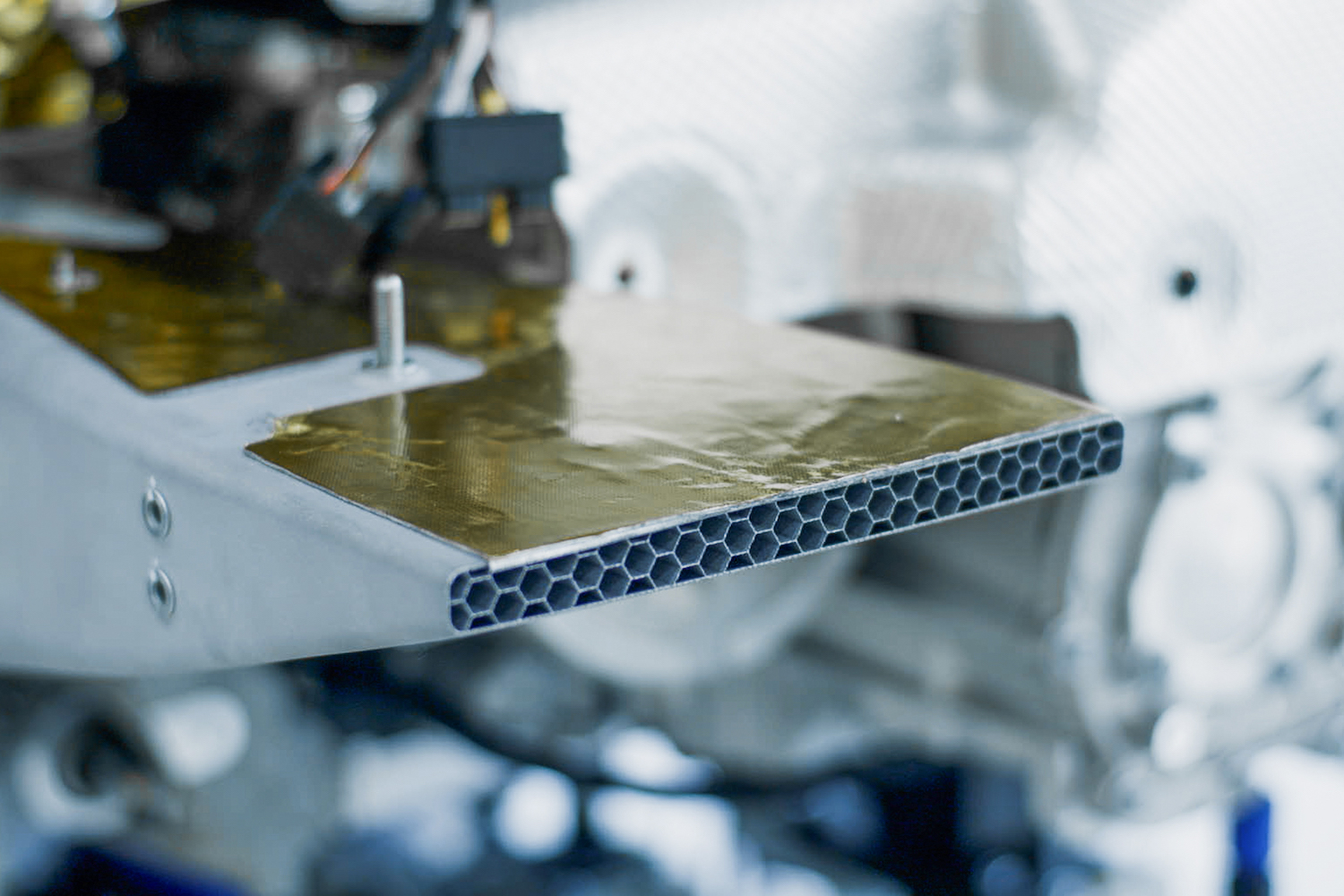

The rear of the hypercar exemplifies Bugatti’s integration philosophy. Where most vehicles use a solid crash beam, the Tourbillon’s rear diffuser itself incorporates two state-of-the-art 3D-printed metal structures that are engineered to absorb crash energy.

Another distinct detail in the Tourbillon’s packaging is the suspension design, which features airfoil-shaped components partially exposed to airflow to support aerodynamic efficiency. Traditional components would disrupt airflow, but Bugatti’s use of 3D printing and AI-driven design optimization enables strong yet aerodynamic wishbones.

Software and AI are optimizing the shape of Bugatti’s parts. In the Tourbillon, it allowed the engineers to remove material atom by atom, leaving only what is absolutely necessary. In areas like the upper suspension components, this results in organic microstructures engineered for maximum strength and minimal weight.

From the angled V16 engine to the topologically optimized suspension, the Tourbillon’s packaging is more than engineering, it is Bugatti philosophy in practice. Every decision was made to ensure a holistic, integrated machine. The result is a hypercar that pushes not just what’s possible in automotive design, but what’s imaginable.

‘The Bugatti Tourbillon focuses on both individual components and how they work together to enhance to the overall car in terms of weight, packaging space, aerodynamic efficiency, downforce, performance. It was not an easy task for the team, but the result is outstanding.’