Škoda Motorsport presents a new all-electric racing car concept: the Enyaq RS Race. Rooted in the Czech brand’s racing DNA, this concept supports the development of innovative technologies and sustainable materials, serving as a pilot project for future production models. The lower and wider concept car incorporates innovative, sustainable biocomposite parts that provide the same rigidity and weight advantages as carbon fibre, contributing to an overall weight reduction of 316 kg compared to the Škoda Enyaq Coupé vRS on which it is based.

Johannes Neft, Škoda Auto Board Member for Technical Development, says: “The Škoda Enyaq RS Race was developed completely in-house by Škoda Motorsport. Based on the Enyaq Coupé vRS production model, the car features a distinctive design with strong racing DNA, enhanced aerodynamics and excellent acceleration. In terms of sustainable solutions, the new concept car also serves as a pilot project for future innovations in series production. The biocomposite parts have led to a significant weight reduction, and we are trialling them in motorsport, including in the current Škoda Fabia RS Rally2, with a view to future implementation.”

An all-electric race car defined by the motorsport DNA of the Škoda Fabia RS Rally2

Škoda Motorsport engineers have developed an all-electric racing car that closely matches the handling and interior space of the successful Škoda Fabia RS Rally2. Škoda’s racing DNA and the rigorous demands of motorsport continue to push the boundaries of technical innovation.

Development of the Enyaq RS Race began in 2023. The project showcases Škoda’s activities in the field of electrified motorsport, driving progress towards a more sustainable future. Based on the Škoda Enyaq Coupé vRS, the concept car uses the same electric powertrain but is 70 mm lower, 72 mm wider at the front, and 116 mm wider at the rear. Most importantly, it is significantly lighter than the production model. Biocomposite parts, incorporating flax fibres in both the body and interior, help to reduce the car’s weight. Additionally, the concept benefits from numerous visual and technical modifications, including a wider, lowered chassis, redesigned bumpers, as well as modified shock absorbers and springs. A completely new high-performance braking system, racing seats, and a roll cage ensure the highest possible active and passive safety. The darkened front headlights feature the distinctive Škoda Motorsport logo, with the headlight housings modified to accommodate the larger wheels. The rear lights have also been darkened. In the Škoda grille, the production model’s Crystal Face has been replaced by a single elongated LED strip connecting the two headlights.

Biocomposite parts: reducing weight and enhancing sustainability

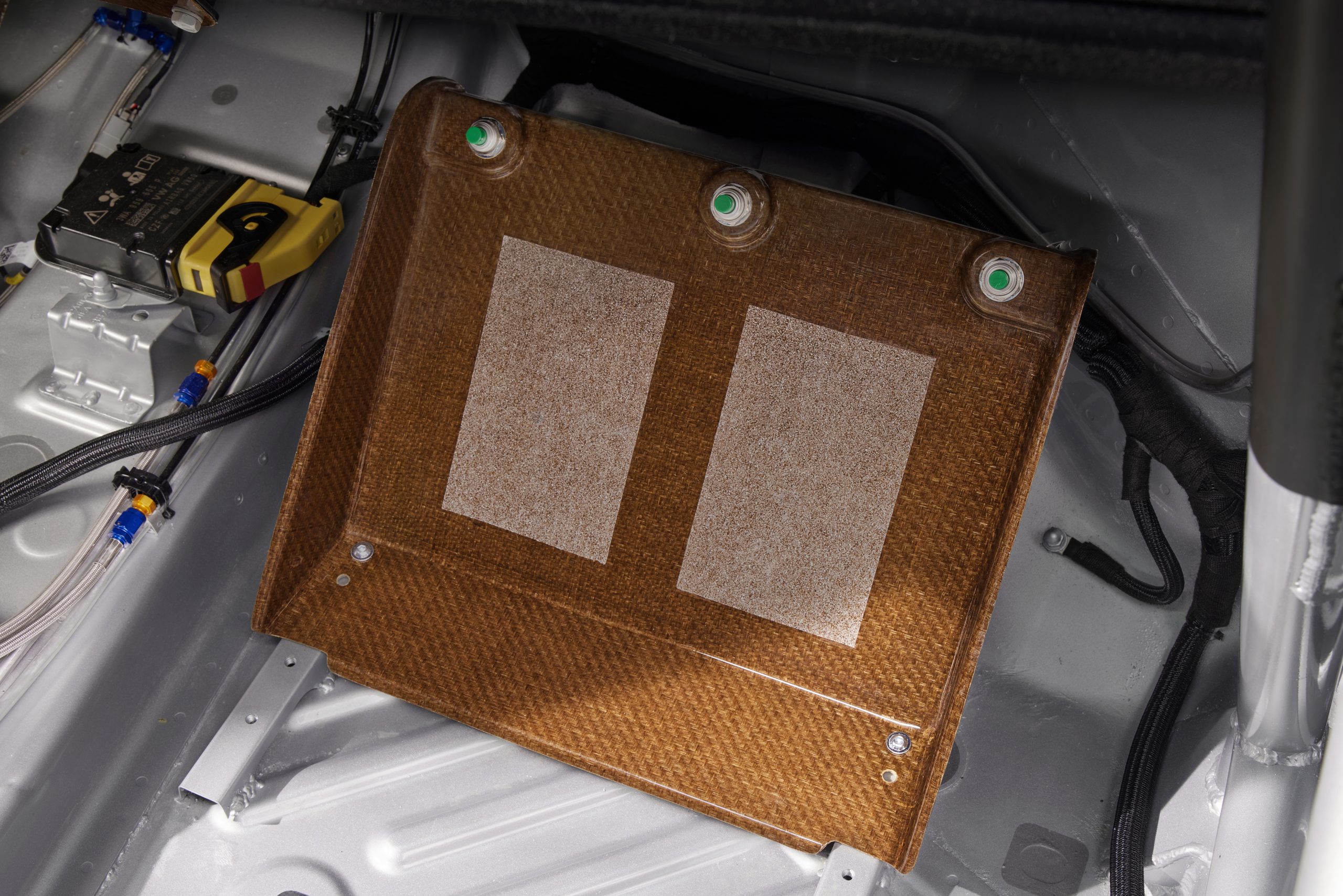

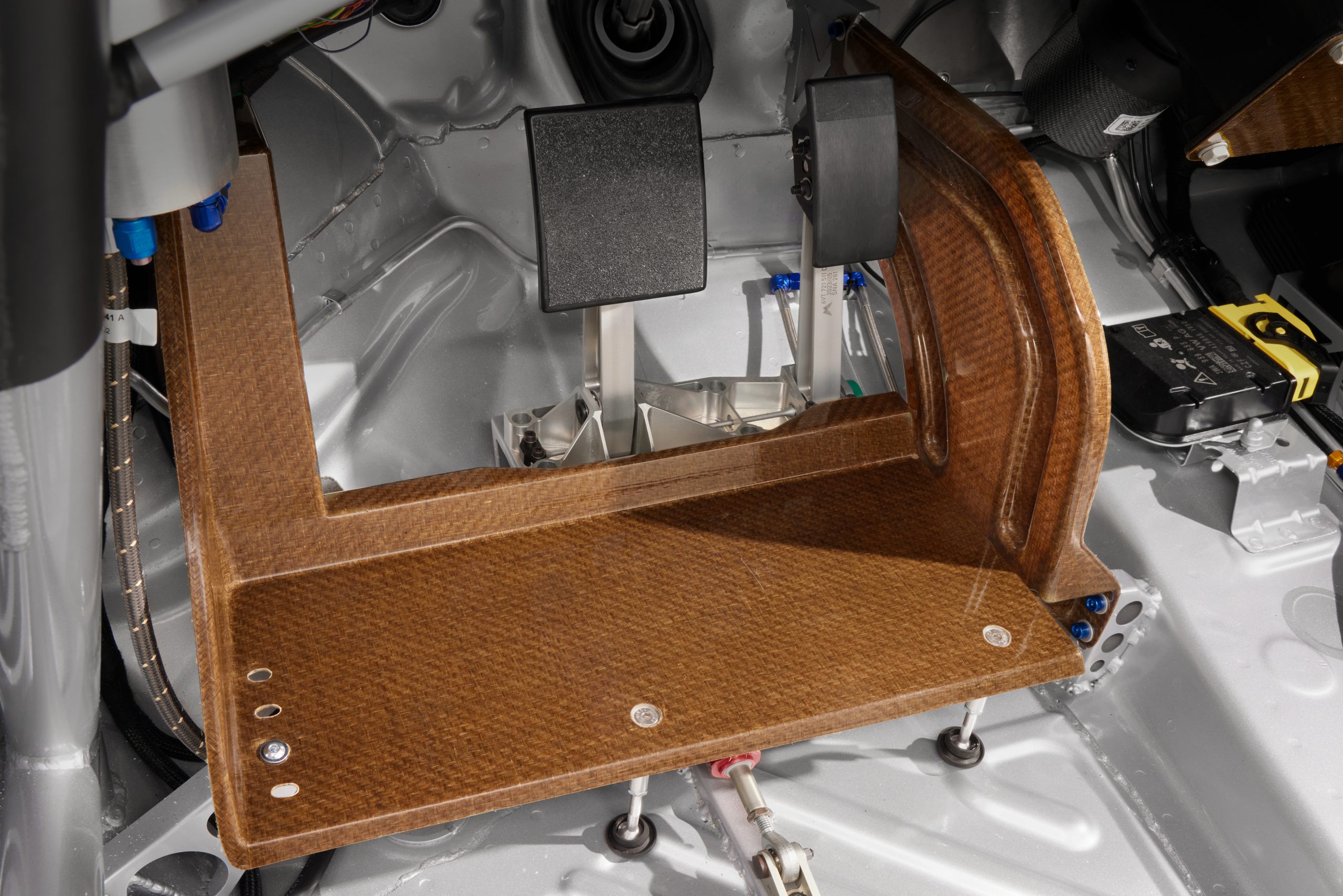

To reduce the weight compared to the production model, Škoda Motorsport engineers employed innovative and sustainable materials, removing all components not needed for the car’s intended use. Additionally, they incorporated side and rear windows made of lightweight polycarbonate. These measures together resulted in total weight savings of 316 kg. The sustainable biocomposite parts, developed in collaboration with Škoda’s motorsport partner Bcomp, are used in the bodywork, including the bumpers, fenders, roof, roof vent, and rear wing. These lightweight materials are also applied in the interior, such as the dashboard, door panels, and footrests for the driver and passenger. Additionally, the standard model’s panoramic glass roof was replaced with a biocomposite panel.

Sustainable flax fibre components: a carbon alternative

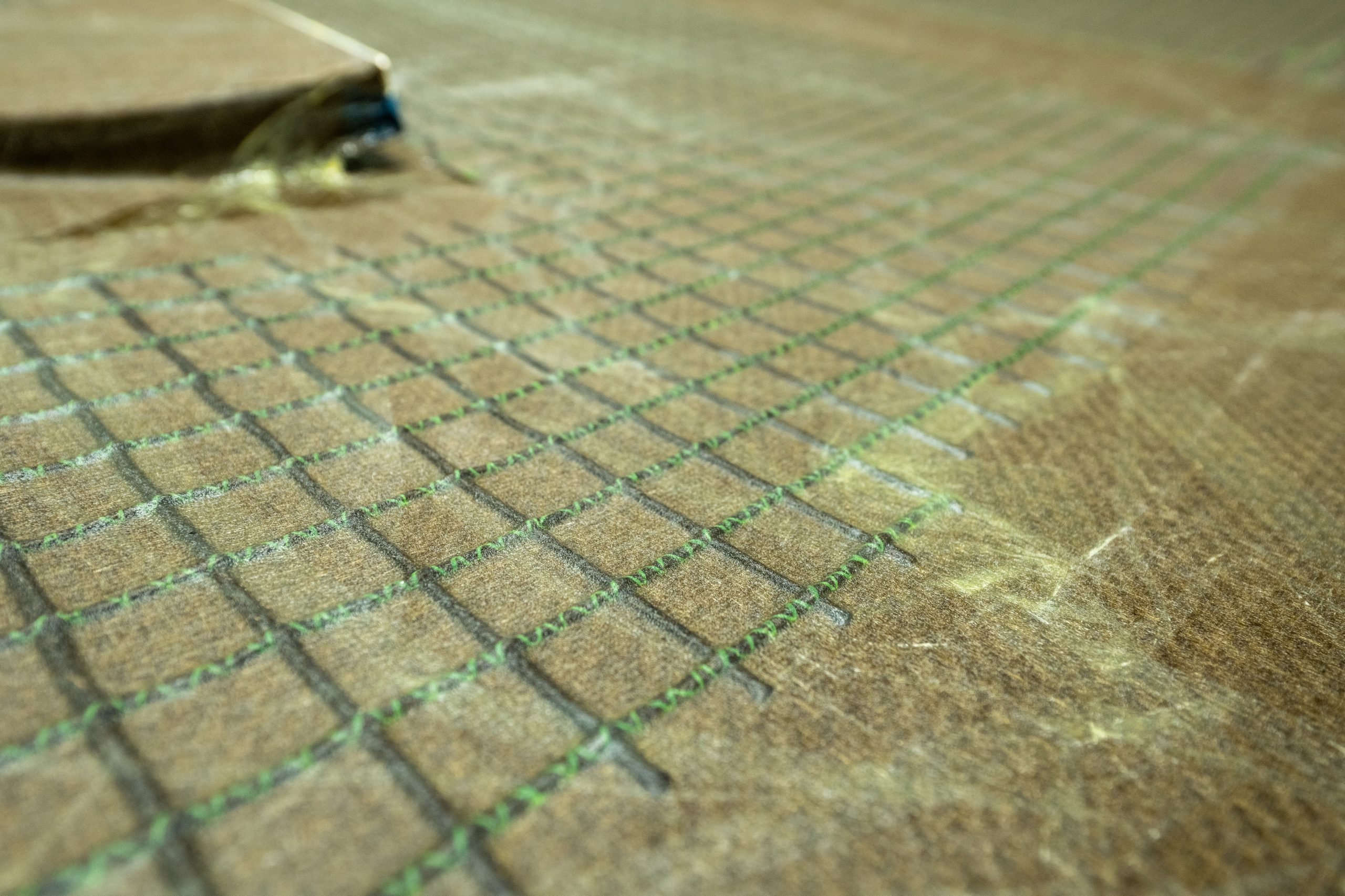

A total of 16 vehicle components are made from sustainable materials, with natural flax fibres replacing carbon in both the interior and the exterior. These are tested under the most challenging racing conditions, for instance in the Škoda Fabia RS Rally2, alongside sustainable lubricants for engines, motors, transmissions and dampers. One example is AmpliTex, a technical reinforcement fabric made from renewable flax fibres grown in Europe. These woven fibres not only reduce vibrations in the interior and contribute to weight reduction but also serve as a visually appealing design element. Moreover, the fibres are processed mechanically rather than chemically, and flax cultivation has a significantly lower impact on the soil compared to other crops.

Bcomp’s PowerRibs™ technology utilises extremely lightweight, high-performance natural fibres also made from flax. PowerRibs™ combine maximum stiffness and minimum weight by creating a 3D structure to reinforce the thin-walled panels of the car body. The benefits include raw material savings, weight reduction, and lower production costs due to using fewer consumables. The material offers comparable rigidity and weight advantages to carbon fibre while reducing CO2 emissions by approximately 85%. This is the first time Škoda Auto has used this material for large, complex components such as the front wings, side panel and bumpers. The engineers also made extensive use of 3D printing in preparing and producing the prototype, using recycled materials such as nylon and CO2-neutral biodegradable biopolymer filaments.

Aerodynamic optimisation of the bodywork

To create the body of the Enyaq RS Race, individual bodywork parts were taken from the production line, redesigned from scratch, and reassembled. In addition to the roll cage made of high-strength chrome-molybdenum steel—which reinforces the body and protects the occupants—the concept car features other safety elements derived from the Škoda Fabia RS Rally2. These include Atech racing seats with six-point seatbelts, safety door filling, and an automatic fire extinguisher. Like WRC rally cars, green and red lights on either side of the vehicle indicate the status of the high-voltage system. The ride height has been lowered by 70 mm, and special protective skids on the underside of the vehicle prevent excessive wear to the chassis components and protect the battery.

The aerodynamics package includes a large rear wing, an aerodynamically optimised roof, and a NACA air intake channelling air into the interior. Small winglets at the rear of the roof direct airflow straight onto the rear wing. The air intake for the cooling system has also been redesigned, with the front section now completely solid and air drawn in through the lower part of the bumper, necessitating a tilted radiator wall. Redesigned bumpers with two additional air curtains at the front, wider fenders, and a new rear diffuser along with the large rear wing increase the downforce, improving drivability at higher speeds. Turbulence around the wheels is minimised by wing-shaped air-guiding elements, while ventilation grilles in the front and rear wheel arches enhance both aerodynamics and brake cooling. The Enyaq RS Race can also be fitted with aerodynamically optimised wheels.

Race-ready adjustments: handbrake, suspension, and limited-slip differentials

Škoda Motorsport experts have adapted several components of the Enyaq RS Race. For example, the production model’s brake system has been replaced with a high-performance setup, featuring carbon-ceramic brake discs, ten-piston callipers at the front, four-piston callipers at the rear and a new brake cooling system. Moreover, the concept car has been fitted with a rally-type hydraulic handbrake with a long lever and the pedal system from the Škoda Fabia RS Rally2. Instead of the standard DCC suspension, a special sports suspension has been installed, allowing for individual adjustments to spring stiffness, compression, and rebound settings.

The 20-inch wheels are fitted with low-profile tyres. The two electric motors, delivering a combined output of 250 kW, and the 82 kWh battery are identical to those in the production model. Like the Škoda Enyaq Coupé vRS, the top speed is 112 mph (180 km/h), but the lighter Enyaq RS Race can now accelerate from 0 to 62 mph in under five seconds.

Enhanced steering and controls for on-track performance

The completely redesigned interior is inspired by the Škoda Fabia RS Rally2 and also includes a modified infotainment system. Featuring new buttons, the racing steering wheel resembles the one from the successful customer rally car. Instead of the progressive rack-and-pinion steering used in the Enyaq Coupé vRS, the Enyaq RS Race is fitted with linear steering, with adjustable steering weight controlled via software, and the drive ratio has been optimised for racing performance. The drive selector and central panel for starting the car and activating the automatic fire extinguishing system are positioned between the seats in this two-seater vehicle.

Havas sound system: amplified for an authentic motorsport experience

The Enyaq RS Race features a Havas premium sound system that incorporates a digital sound amplifier to deliver the characteristic, exhilarating motorsport sound. This entirely new system is significantly louder than the unit in the production Enyaq Coupé vRS model, and its note can be changed. The sound is also activated at speeds above 18 mph, ensuring an exciting acoustic experience throughout the drive.